Application

filling pipe: round or rectangular

types of seal: centered lap seal or centered distant or turned down fin seal

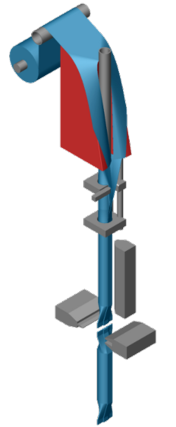

A forming head is not a finished forming shoulder but the first step in the forming process that forms the film into a flat tube. The second step then moulds and calibrates the tube into its final form. The required parts have to be manufactured and integrated into the machine by the customer himself.

The forming parts have to be adjusted precisely to the forming head . We supply a sketch to show where the forming parts should be situated. Finally it depends on the customer where the forming parts are positioned.

Especially low-priced we offer a series of standardized forming heads suitable for bags with a flat bag width from 13 mm to 42 mm. Get an overview and have a look at the data sheet of the uForm series (pdf file)

Benefits

- competitive low investment costs

- reduced forming length and

- improved film run compared to a forming process without a forming shoulder

- applicable to multilane machines

Limits

- qualified personnel for installation and operation required

- inferior film run compared to a forming process with a forming shoulder

Sample application

Multilane stickpack machine with ten forming heads