Aseptic packaging requires the application of hygienically designed forming shoulders. There must not be any inaccessible gap. Each part of the forming shoulder has to be accessible all over.

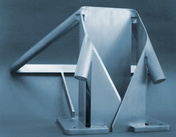

Forming shoulders for these requirements consist of milled parts. Ideally they consist of one piece only.

We keep the contact area of the film with the forming shoulder as small as possible. Mainly the film is spanned freely with as few parts as possible to support the film. This parts are hygienic designed. Using only a few small parts the material and manufacturing costs could be reduced.

Using precise milled parts the forming shoulders of a series are absolutely identical and could be reproduced exactly if needed.

To increase the wear resistance of those high-quality forming shoulders we offer a coating with diamond-like carbon (DLC) if required.