Whether round, rectangular or oval – symmetric or asymmetric – almost every cross-section of a film tube can be designed. The longitudinal seal can be formed as lap, distant or turned down fin or end-to-end seal. It could be situated in the center of the bag or shifted to the side.

You can instantly reduce the adjusting effort and choose infeed rolls that are mounted to the forming shoulder directly. The integration of the forming shoulder into your packaging machine is simple.

Short forming heights are especially good practicable for resilient film materials like plain plastic and centered longitudinal seal.

Basically forming shoulders are milled completely if the flat bag width is smaller than 60 mm. In this case every stickpack forming shoulder is as precise as possible.

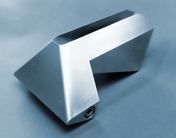

Milled parts are applied to forming shoulders that are made out of sheet metal if a high accuracy of the forming process is required. This might be necessary to form edges.

Get an overview of our product range